The crucial role of component identification and traceability in the industrial production process

28-04-2021

Granting the traceability and identification of parts, components and complete products is an essential requirement in the management of the idsutrial productiion process

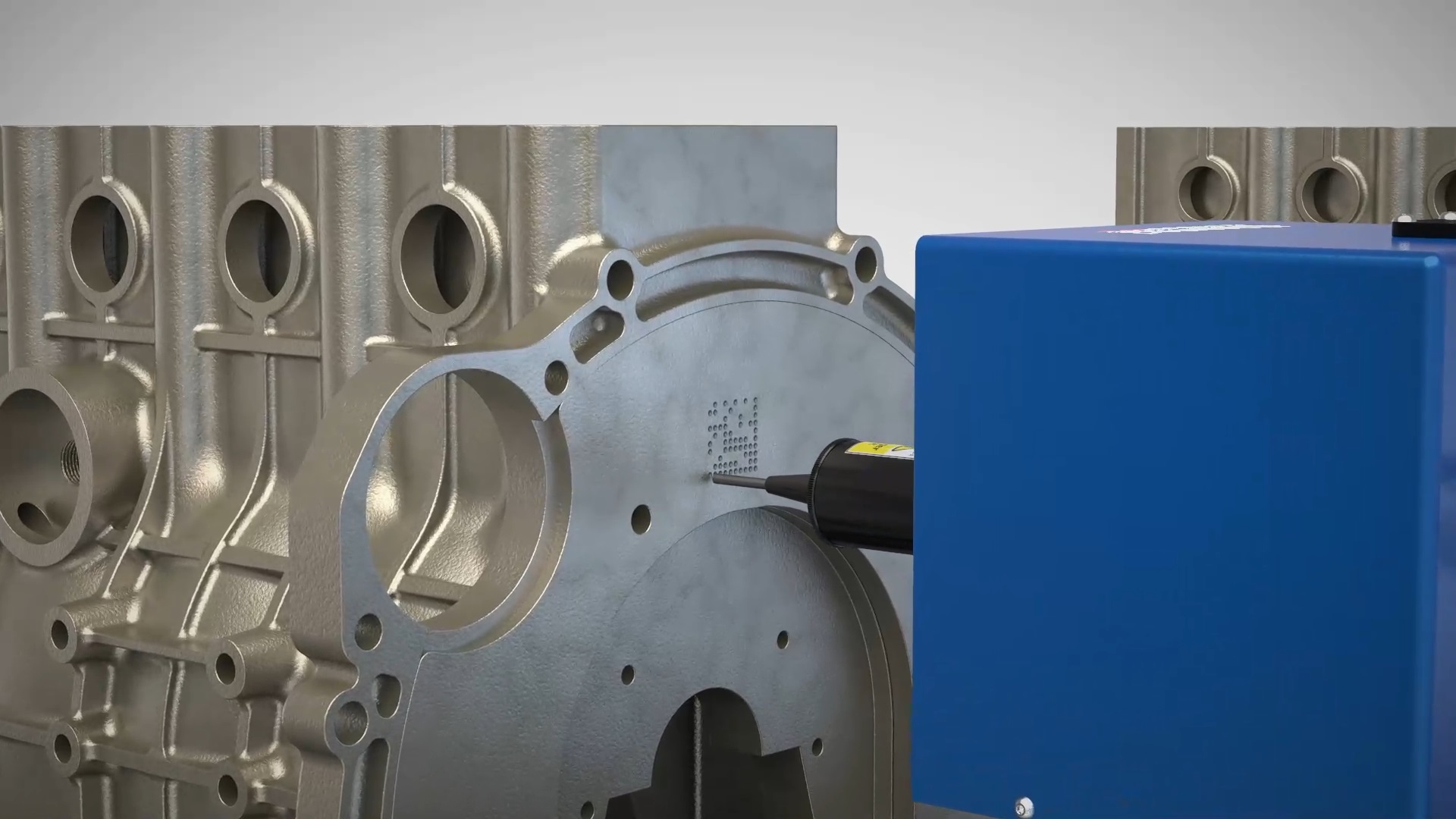

For several idustries (such as aircraft, railway, defence, automotive, etc.) the traceability and identification of the industrial products need to comply with compulsory requirements: in fact, component tracking and identifying throughout the prduction chain (including the exectuion methods and criteria) is disciplined by mandatory rules.

Any supplier involved in the mentioned industries needs to follow these rules strictly, to be allowed to commericialize its products.

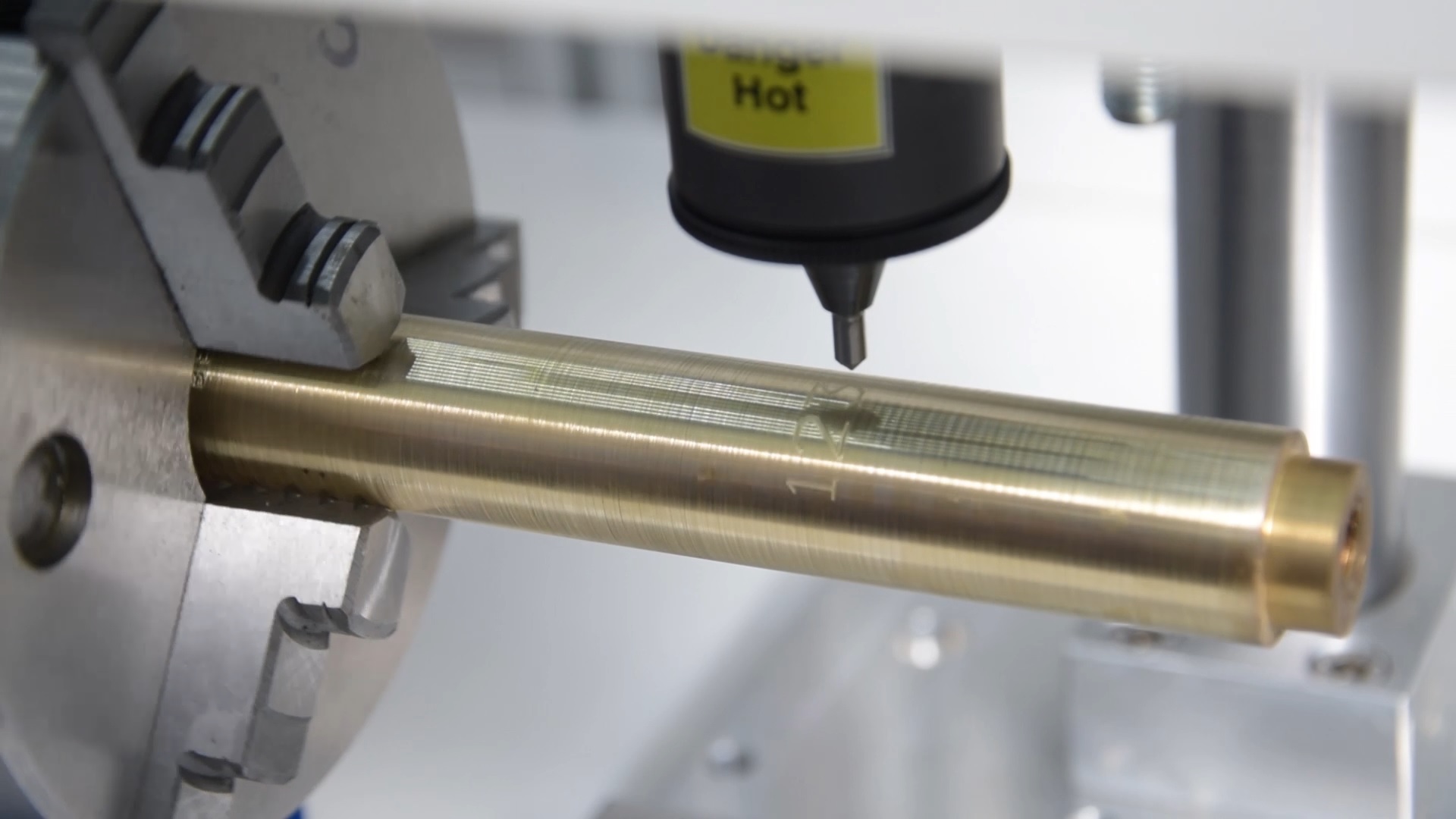

In different cases, even if the product traceability and/or identification is not required by law, they are substantially mandatory, as they are included in the Customer's supply specifications (e.g. in packaging, hydraulic and mechanical transmission industry, etc.). Pending these requirements, the supplier/subcontractor should grant the traceability / identifcation to keep its competitiveness in those markets.

It's quite easy to understand that the capability to grant the tracking and identifying of industial parts, components and complete products opens the opportunity to access the supply chain of well-established companies, so achieving considerable and steady income (even increasing through the timeline).

In general, also when the traceability and identification are not required by law and/or supply specification, they bring several adavtages:

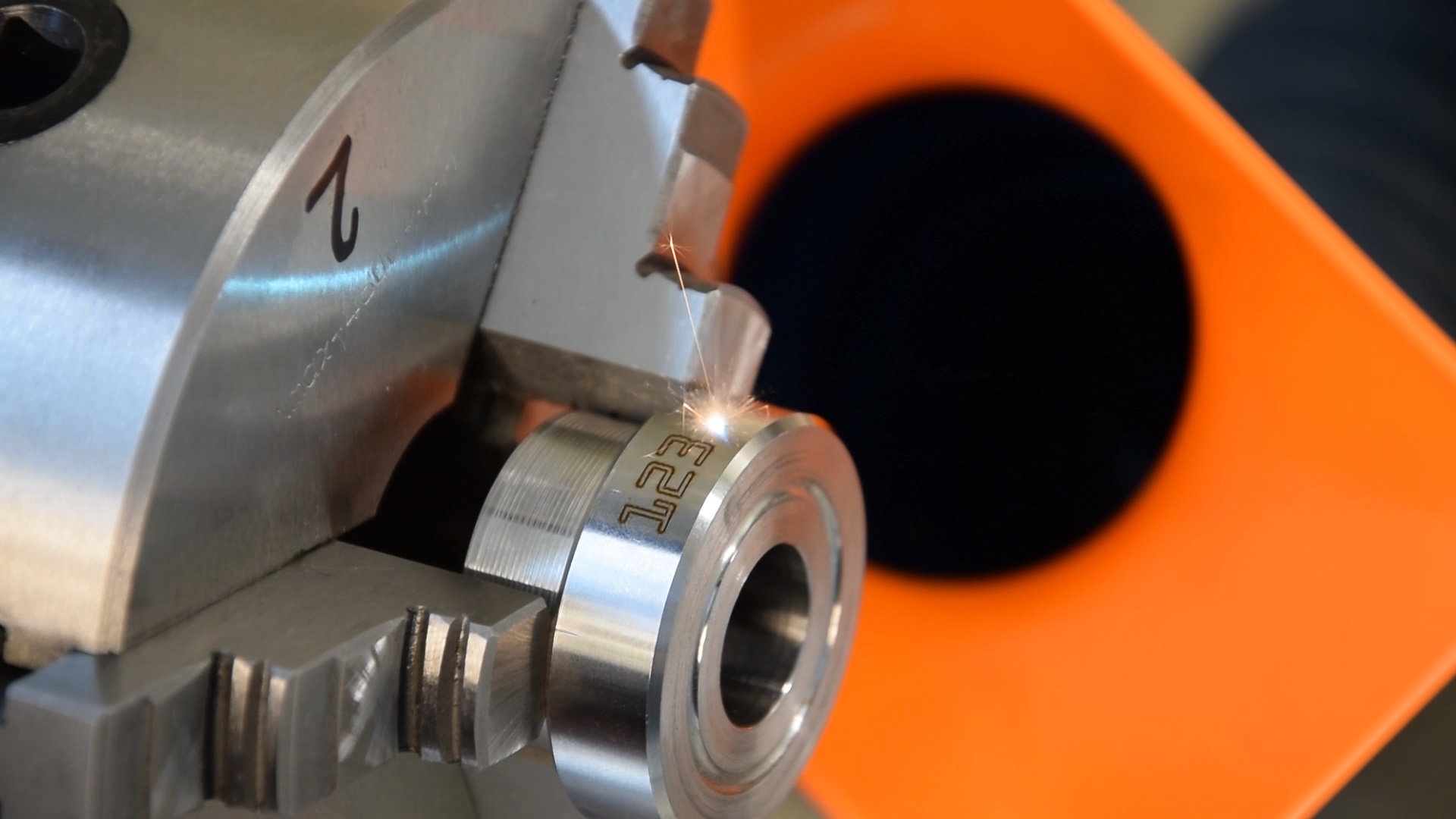

• First of all, they grant the authenticity of the component against any attempt to replicate, imitate or counterfeit.

• The part tracking makes quicker and easier (and cheaper, of course) the ex-post troubleshooting, especially in case of remote assistance.

• An effective tracking and identification procedure, joint to a proper data collection process, allows to individuate repetitive defects or sub-optimizations, reducing non-quality costs proactively and progressively.

• Cosidering the day-after-day-increasing remote Customer relationship management, the product traceability and identification make quicker and more accurate the supply identification, especially when it is far in time and/or if the Customer can submit only summary information, reducing the feedback time and allowing the most precise indivituation of the next steps required, so improving the after-sales service (and the Customer's satisfaction too).

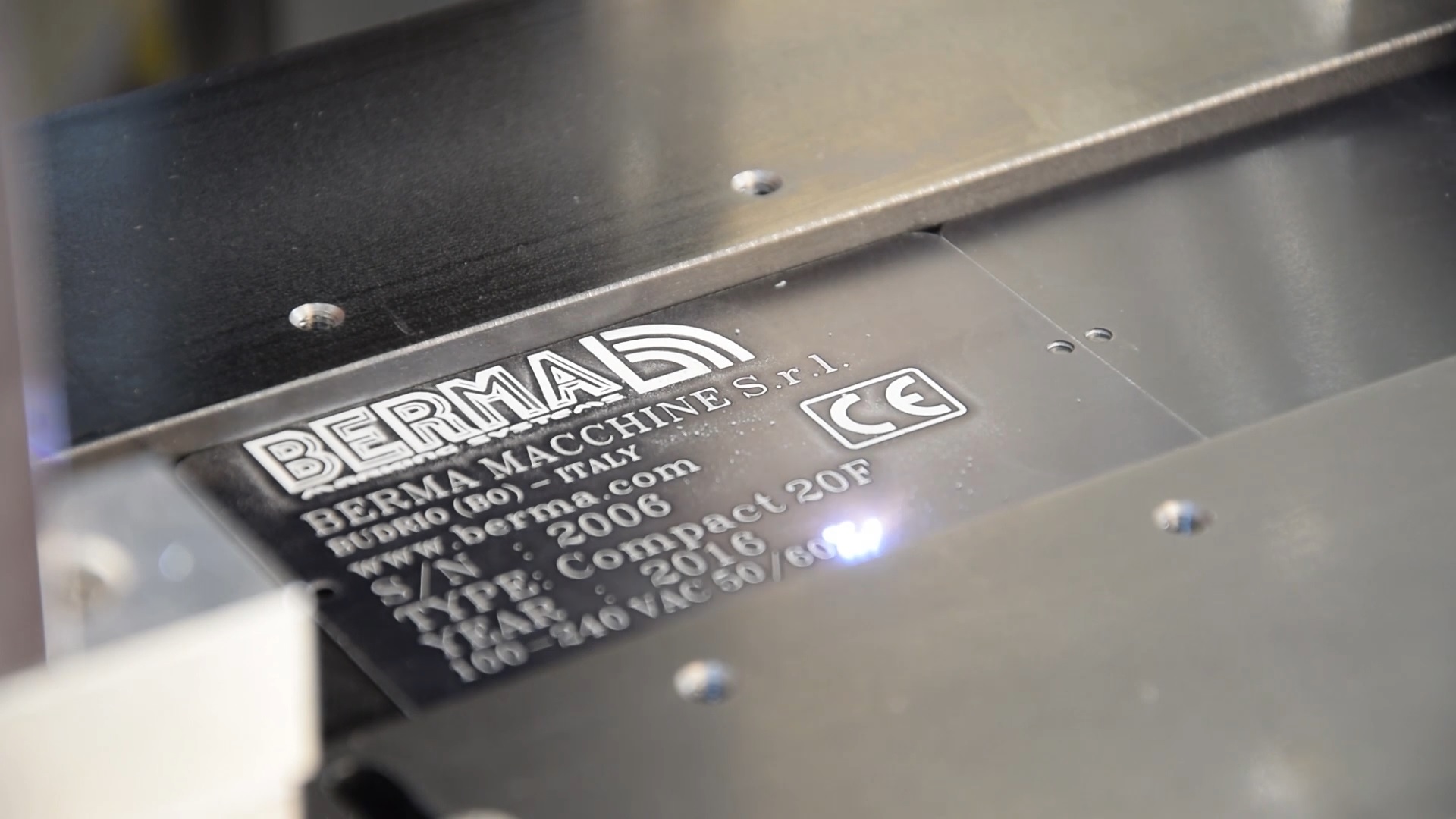

• Moreover, product traceability can improve the Corporate Image. In fact, besides the ID code it is possibile to reproduce the Manufacturer's logo/brand very accurately. This improves the aesthetic features of the product making it "uinique", and increases the Company's brand awareness.

Therefore, granting the traceability and identification of the industrial product represents a profitable investment, allowing to comply with law and/or market requirements ad opening growth and value-ladder opportunities to the Company and its products.