Which technology can be used to identify and track industrial products

03-06-2021

Besides the regulation requirements and/or the commitment specifcations, granting the identification and traceability of parts and comopnents througout the production process brings considerable opportunities to increase the value of a company and its products.

To comply with these requirements and grab this opportunity proeprly, the marking technology has a crucial role, especially in the right calibration of an investment highly impacting on both product and process.

The accuracy in analysing every single side of this choice becomes basical:

• PRODUCT TECHNICAL SIDES: physical features (wight, dimensions, material hardness, etc.) and prodcut complexity (wether is composed by a unique part or more, and so on).

• PROCESS TECHNICAL SIDES: required productivity (ouput per time unit), numerosity and complexity of the information to be managed, number of phases where marking is required, etc.

• “COMBINED” SIDES: marking area position and dimensions (also considering the information to insert), and so on.

Moreover, it is reccommendable to take in cosideration FURTHER ELEMENTS too:

• Marking deepness (sometimes needs to comply with specific regulations/specifications)

• Marking time

• Occupancy available within the production line layout

• Other issues (such as noise level, aesthetic requirements, etc.)

There are several industrial marking technologies available, but to be suitable to grant the product identification/traceability it is necessary to ensure an indelible marking: therefore, we have to focus on the following options:

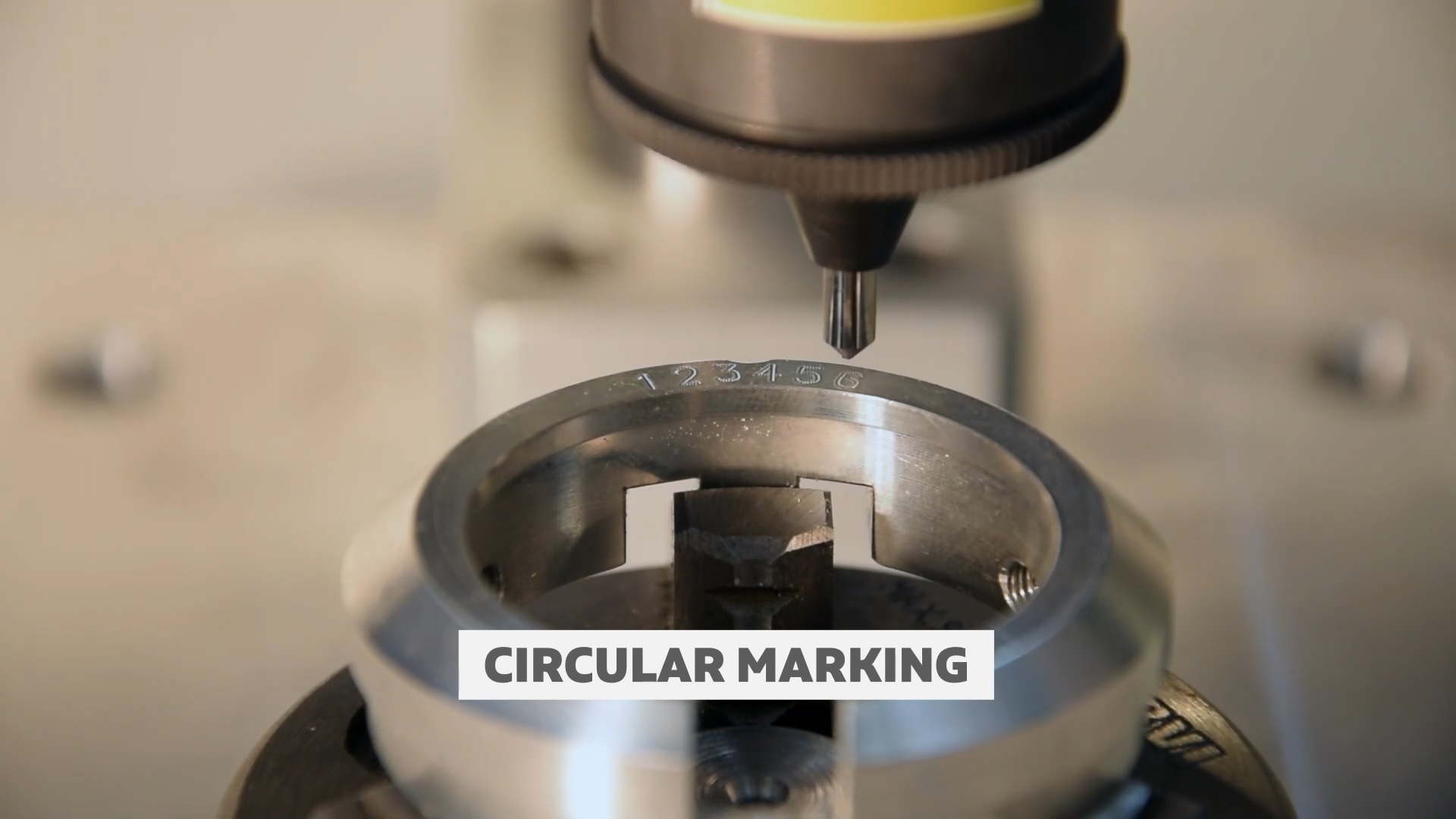

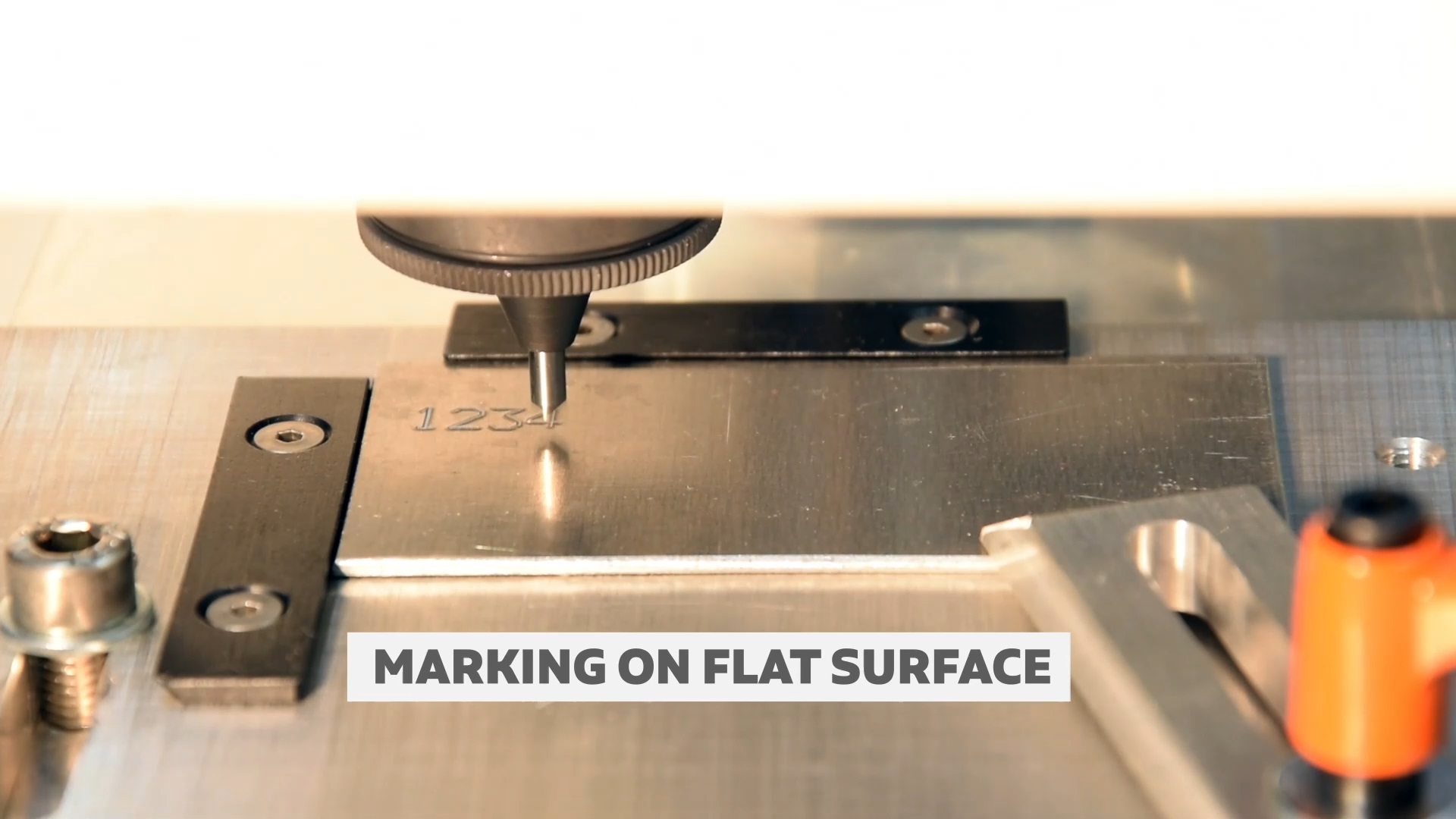

• DOT PEEN / SCRIBING MARKING, operated by a stylus that deforms mechanically the surface to be marked;

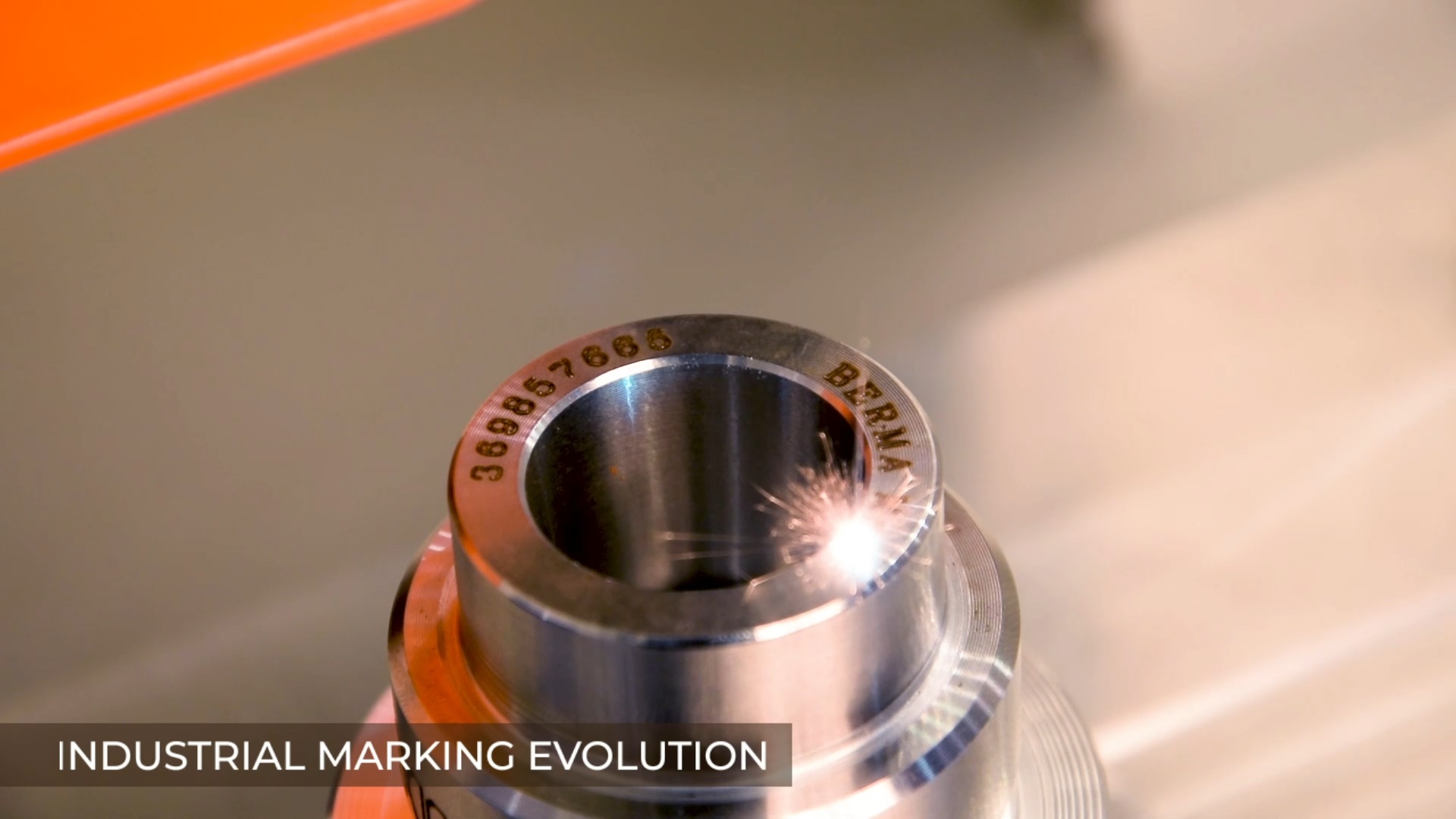

• LASER MARKING, performed by a collimated beam of energy emitted by a specific source, which alters the molecular structure of the surface to be marked.

Through the analysis of the above mentioned sides, both taken individually and by evaluating the reciprocal interactions, it is possible to determine which marking technology is possible (or more appropriate) to apply.

Some types of production (such as railway wheels, or chassis for vehicles) feature quite standardized characteristics requiring well-defined and consolidated technologies, while in other cases it is necessary to carry out ad hoc evaluations to identify the most suitable technology.

In general, dot peen and laser industrial marking technologies present specific peculiarities:

• Industrial laser marking can reach extremely high productivity levels, guarantees higher chromatic contrast of the mark (increasing its visibility), and minimizes the impact on the surface of the product (this technology does not generate direct touch to the surface to be marked), with positive effect also on the noise level. It also requires very low maintenance operations over the time.

• Industrial dot peen marking is easier to install and reduces processing waste (up to zero in the vast majority of cases), and it's generally cheaper.

The combination of all these sides (product, process, operational and technological) makes possible to precisely identify the type of industrial marking machine that maximizes performance and increases the added value of traceability and identification of industrial products.