LEAK TEST

DEVICES

ABSOLUTE PRESSURE DECAY METHOD

BERMA technology for your production process

Our leak testing devices are the result of an accurate design and industrialization process. They are perfectly adaptable to any layout and production line, perfectly legible and easy to use, to ensure maximum productivity and reliability of the production process.

ID-Leak devices & accessories guarantee precise and reliable leak testing in any application field.

Download ID-Leak Catalogue

MADE IN ITALY TECHNOLOGY

ID-LEAK testing instruments are the result of the combination of BERMA experience and the knowledge gained in the production process control and traceability systems. They are entirely designed and manufactured in our plants in Budrio (Italy), 100% Italian ideas, technologies and skills!

COMPACT AND PRECISE

Reduced dimensions, selected materials and components, highest accuracy in design and manufacturing: for this reason ID-LEAK test devices grant maximum measurements precision and repeatability for the highest reliability of your production process.

EASY TO INSTALL AND USE

Quick installation, long-lasting and accessible pneumatic connections, clear and readable graphic interface, intuitive and powerful data managenment software: ID-LEAK tools are immediately operational to effectively implement leak tests on your products.

CONNECTIVITY AND INTEGRATION

ID-Leak instruments are equipped with different connection technologies: RS-232 serial (with proprietary and standard protocols such as MODBUS), digital I/O and TCP/IP (also Wi-Fi) to allow a rapid and precise data exchange at any time: ID-LEAK testing devices can be easily integrated with MES / ERP systems, improving the productivity of your processes.

SUPPORT AND ASSISTANCE

With ID-LEAK equipment you are never alone!

Our systems can be equipped with a remote technical support function (via SupRemo software and HMI remote control functionality) which allows us to intervene promptly.

Furthermore is active a dedicated assistance telephone line, making us immediately managing all service requests.

-

ID-Leak - leak test devices

- Test method D1 EN1779, absolute pressure decay

- TCP/IP Wi-Fi connectivity – Modbus - Profinet

Reliability, accuracy, ease of use and extensive connectivity

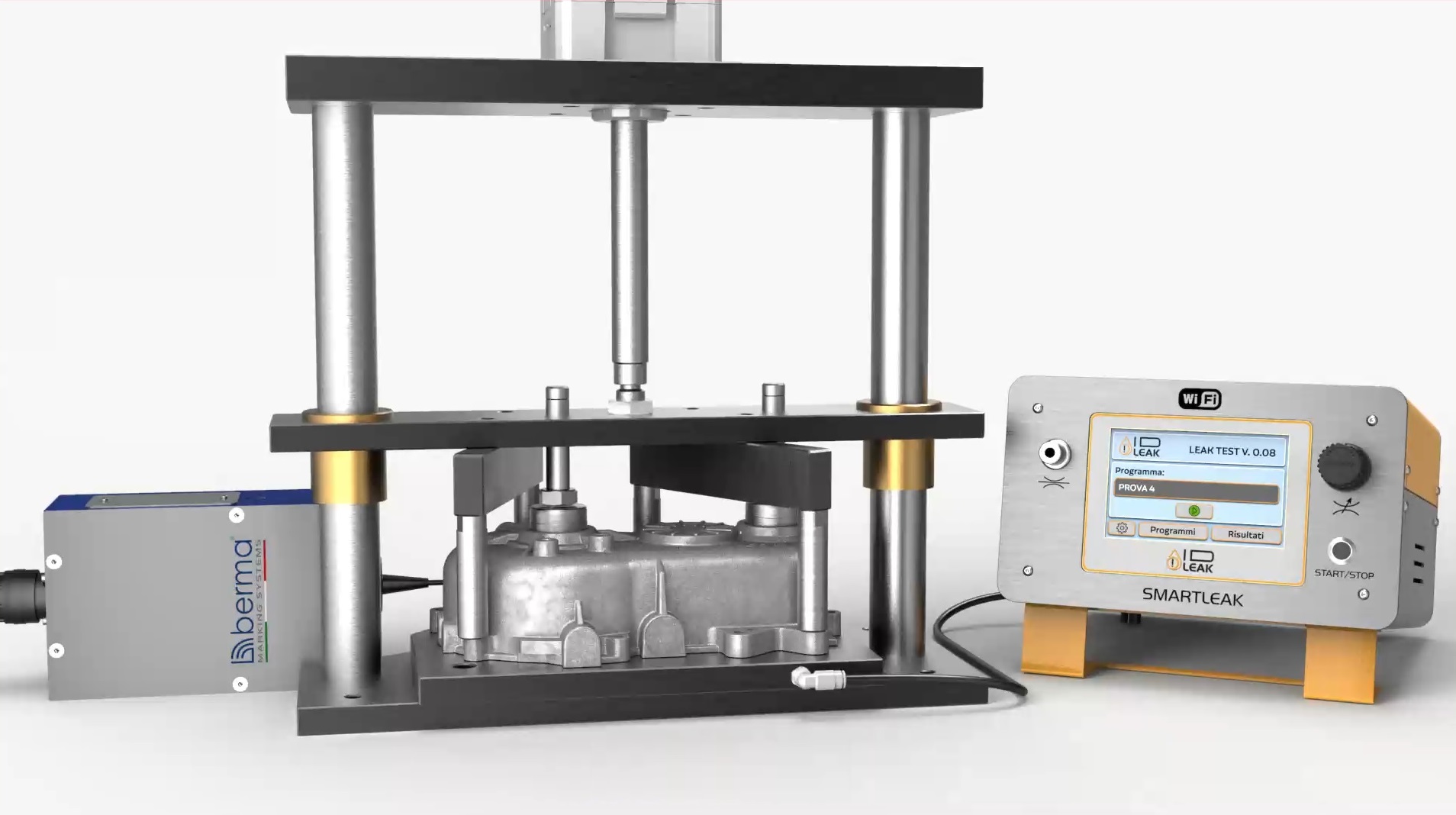

“SMARTLEAK” is a measuring instrument designed to perform leak tests with pressure decay measurement (D1, EN1779).

The 5 “resistive touchscreen display allows real-time viewing of the test progress and makes programming and use of the device simple and immediate.

The high measurement resolution allows you to test different types of parts, in various sectors, quickly, objectively and always traceable.

The possibility of interfacing external automations through digital I/O, ASCII protocols, fieldbus and barcode readers through the serial port as well as the Wi-Fi TCP/IP connectivity, make “SMARTLEAK” a complete, reliable and integrable tool in any production system 4.0. -

Leak test accessoires

- Maintenance of testing standards

- Traceability and management of resultsOur accessories, to be used together with our testing and leak testing instruments, allow us to maintain a high level of measurement reliability and recording and traceability of test results.

SMARTLEAK-M

SMARTLEAK-M

SMARTLEAK-E

SMARTLEAK-E

Plugging equipement

Plugging equipement

Calibrated Leaks

Calibrated Leaks

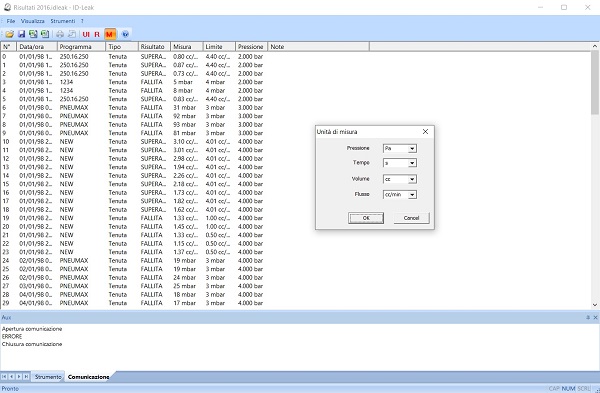

Results traceability software

Results traceability software