Supreme

// Home // Products // Industrial marking machines // Fiber Laser Marking Machines // Supreme

The multi-axis laser marking machine SUPREME is designed to identify several small workpieces on a pallet or to identify big workpieces that need to be marked in more than one spot.

It is equipped with fiber 1060 - 1080 nm laser sources from 20W to 100W power with Q-switched or MOPA technology, allowing the most suitable configuration for different needs.

It is suitable to work on every kind of metals and a lot of types of plastic.

With this device is possible to create linear and circular alphanumeric texts, logos, barcodes and 2D codes (Data Matrix and QR code).

The controlled movement of the laser scanning head along the X and Y axis allows to obtain a large working area that it is extended almost the entire width of the worktop.

SUPREME-FX: marking area up to 562 x 174 mm

SUPREME-XL: marking area up to 1044 x 424 mm

The M8 drilling with a constant pitch on the working surface allow to carry out tool changes in an extremely fast and precise way for all BERMA laser marking machine.

In the standard equipment of this marking machine there are: motorized Z axis, illuminated worktop and the fume evacuation set-up.

In the model SUPREME is possible to install the rotary axis device (W) to carry out markings on cylindrical components up to 250 mm diameter or the automatic feeder of plates.

The optical unit of this device has high performance and low consumption that guarantee high density of energy that allow to have a permanent marking in a short time.

The positioning of the markings is facilitated by the integrated red-pointer.

SUPREME multi-axis laser marking system

SUPREME multi-axis laser marking machine, fiber laser source with 1064 nm wavelength and 20W, 30W or 60W laser power

Feature and advantage:

-

Marking Area up to 1044 x 424 mm

-

Illuminated worktop

-

Hardware integrated inside the device

-

USB, RS-232, TCP/IP (optional) connections

-

Stand alone system

-

Possibility of remote assistance

-

Easy to use and program

-

Import of BMP, DXF, DWG, SVG, PLT

-

Laser safety Class 1 Cabin

-

Integrated red-pointer

-

Reduced maintenance

-

Long Laser lifetime

Would you like to learn more?

Contact us“BERMA’s staff help you to find the best solution, standard or customized, for your needs of identification and marking”.

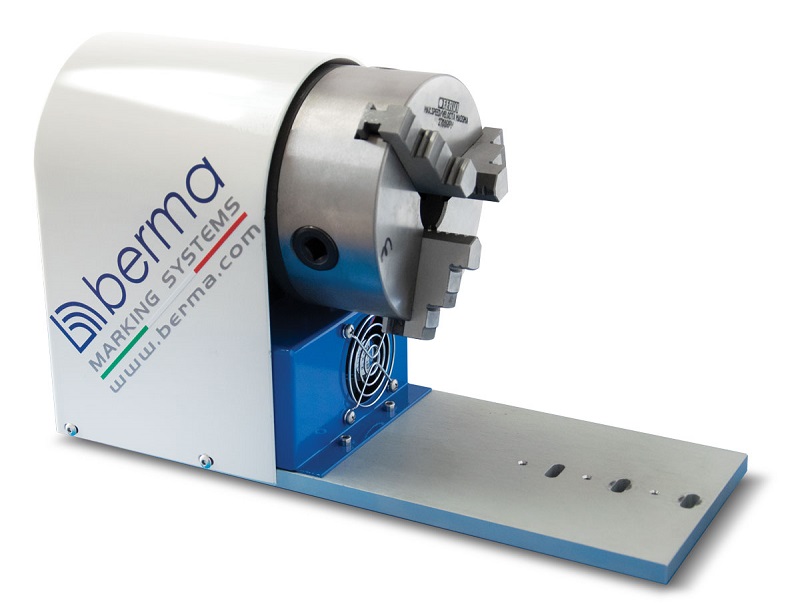

Rotary axis (W)

Rotary axis (W)

Vacuum cleaner systems

Vacuum cleaner systems

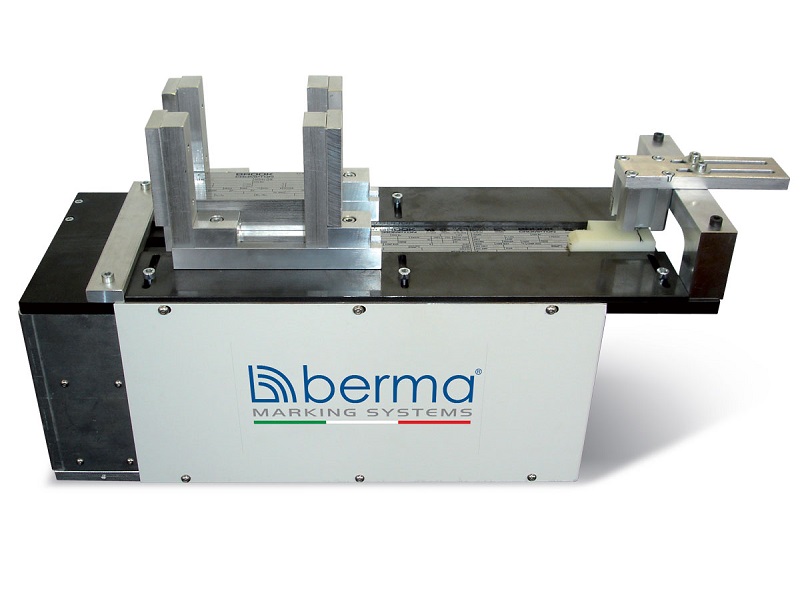

Plates feeder (F)

Plates feeder (F)

netTAP 50 Profinet gateway

netTAP 50 Profinet gateway