INDUSTRIAL MARKING SYSTEMS

LASER, DOT PEEN, ELECTROLYTIC MARKING SYSTEMS

BERMA technology for your production process

Since 1974 we have been designing and manufacturing

The experience acquired in 50 years of activity in the industrial coding and traceability allows us to design and manufacture a complete range of Industrial Marking Systems, for any coding and traceabilty requirement within the production process.

The skill to internally develop hardware and software of our machines has allowed us to create a unique platform for the management of all our marking technologies; dot-peen, scribing and laser.

Download Laser Catalogue

Download Dot peen & Scribing Catalogue

HIGHEST RELIABILITY AND PRECISION

Numerically controlled movement, systems and aids for positioning and previewing and the use of components selected and sized with maximum accuracy allow for clear, precise and long-lasting markings to be obtained on a wide variety of surfaces with different geometric characteristics.

THE TECHNOLOGY MOST SUITABLE FOR YOUR NEEDS

Laser and dot peen marking systems, a wide range of installed powers, layout and dimensions of the working area: we find the best configuration for your production process, customizing it according to your specific needs.

PRODUCTIVITY AND VERSATITLITY

Portable, benchtop, stand-alone models and OEM units to be integrated with servo systems and automations: all your need for precision, time, costs and space occupation optimization, flexibility of use and production volumes can be satisfied with a BERMA industrial marking system.

Marking programming can be carried out directly on the machine, without a PC, and through IDENTIFY3 software (always included in all systems) you can easily manage logos and complex graphics.

INTERCONNECTION

Both proprietary (bermaCMD) and standard (MODBUS) communication protocols for remote control of the marking system, various connection options to computer systems (USB, RS-232, TCP/IP), easy to read, simple and intuitive user interface: BERMA industrial marking systems can be perfectly integrated with your MES / ERP systems, optimizing data exchange and simplifying your job.

SUPPORT AND ASSISTANCE

With BERMA industrial marking systems you are never alone!

You can rely on a fast and competent technical staff always at your disposal.

Our systems are equipped with a remote technical support service (via SupRemo software and HMI remote control functionality) which allows us to intervene promptly.

Furthermore is active a dedicated assistance telephone line, making us immediately managing all service requests.

Download our dot-peen & scribing Catalogue

DOTLITE an GALVOTEK are registered trademark of BERMA Macchine s.r.l. – all rights are reserved

-

Fiber Laser marking machines

- class 1 laser systems

- incorporated remote support

- automatic Z axis control

- systems up to 7 axis

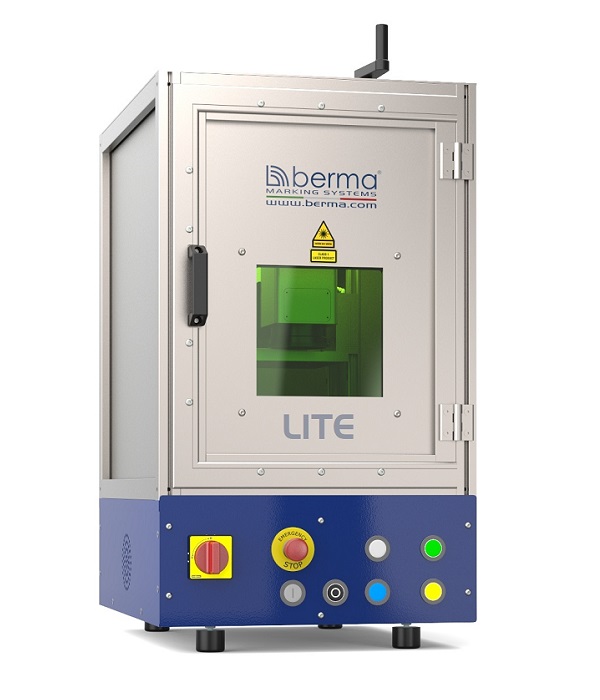

- systems with rotary tableThe Fiber laser marking machine designed and manufactured by BERMA can be used in different environments. These devices comply with Job Safety regulations (CLASS 1 protection cabin – ISO EN 60825-1).

BERMA fiber laser marking systems are equipped with near-infrared fiber laser sources with power from 20 to 100W, depending on the needs of the specific marking/engraving application.

Simple benchtop versions and special high-productivity solutions for laser marking are available with assembly on comfortable wheels that allow the machine to be moved easily.

They are suitable for processing all metals and also many types of plastics. -

Dot peen marking machines

- robust and reliable

- user friendly

- chassis and heavy parts deep marking

- PC software includedDot peen marking machines, made by BERMA, are today a benchmark in the industrial marking and tractability sector.

Benchtop dot peen marking machines are equipped with one or more columns support, which allows you to make an accurate height adjustment, manually using a screw or motorized in the "Z" versions. These devices are compact and reliable and this make its ideal for the user who needs to identify in a simple and indelible way.

Portable dot peen marking machines are suitable for industrial identification of cumbersome and heavy components that cannot be easily moved and moved on a benchtop marking machine. Comfortable and versatile, the portable marking systems produced by BERMA, are characterized by a practical double grip and a reduced weight, resulting very easy to handle and precise on any surface.TOP6 marking machines are characterized by a sturdy mechanical construction that makes it possible to take full advantage of the pneumatic stylus, up to 6 mm in diameter, allowing the creation of very deep and resistant markings for subsequent painting or galvanizing.

-

Integrable OEM marking systems

- Heads with small size and low weight

- classe 4 devices

- MODBUS, Profinet, bermaCMD protocols

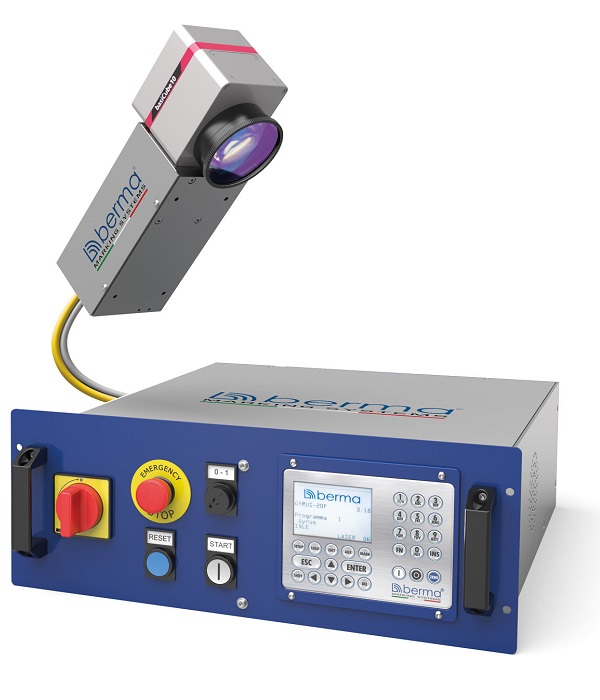

- optoisolated I/O portOEM Marking systems for integration made by BERMA are set for direct connection via RS-232 or TCP/IP and are equipped with several protocols, ASCII (bermaCMD) and Fieldbus (MODBUS) for the remote control of the device.

The synchronization is guaranteed by 24VDC digital I/O available on the specific connector.

All the marking machines for integration made by BERMA are light and have small dimensions. The controller is separated and it can be installed in an easily accessible area.Dot peen and scribing marking machines for integration are designed to be inserted in other machines, robotized cells, production lines and so on.

Laser marking systems for integration are studied to be integrated in other machines or systems and belong to the laser safety CLASS 4.

-

Electrolytic Technology

- economic and professional

- permanent and high-contrast markingsTo give continuity to the activity carried out by the company Giorgio Tenedini, today we present the Signomat electrolytic marking technology. It is an economic and professional solution for high-contrast marking of all electroconductive materials (i. e. metals, aluminium...). Due to low investment costs, markings that are carried out with our marking devices are also extremely cost-effective. Moreover, the marking process allows abrasion-resistant, permanent and high-contrast markings to be accomplished. The electrolytic marking technology is employed in all industries and is excellently suited to the marking of highly sensitive parts (e.g. surgical instruments, implants and products for the food, aviation and automotive industries). Due to the combination of electricity and electrolyte, the image of the marking stencil is marked on the product by means of oxidation. The subsequent use of neutralyte prevents undesired corrosion.

LITE

LITE

MIKRO

MIKRO

Supreme

Supreme

GYRUS

GYRUS

b130

b130

PIKKYO™

PIKKYO™

p80 - p140

p80 - p140

b250

b250

INTEGRA-F (Laser)

INTEGRA-F (Laser)

g130X (Scribing)

g130X (Scribing)

i50 - i200 (Dot peen)

i50 - i200 (Dot peen)

i80-Wi-Fi (Dot-peen)

i80-Wi-Fi (Dot-peen)

Signomat electrolytic devices

Signomat electrolytic devices

Stencils and accessoires

Stencils and accessoires