MIKRO

// Home // Products // Industrial marking machines // Fiber Laser Marking Machines // MIKRO (MY2022)

To mark everything in your precious space

The renewed MIKRO fiber laser benchtop marking system can be quickly and safely installed on a bench or table thanks to the CLASS 1 protection cabin.

The optimized arrangement of the moving parts of the head maximizes the capacity of the loading compartment. The worktop is equipped with M8 holes for quick positioning of the tools and templates.

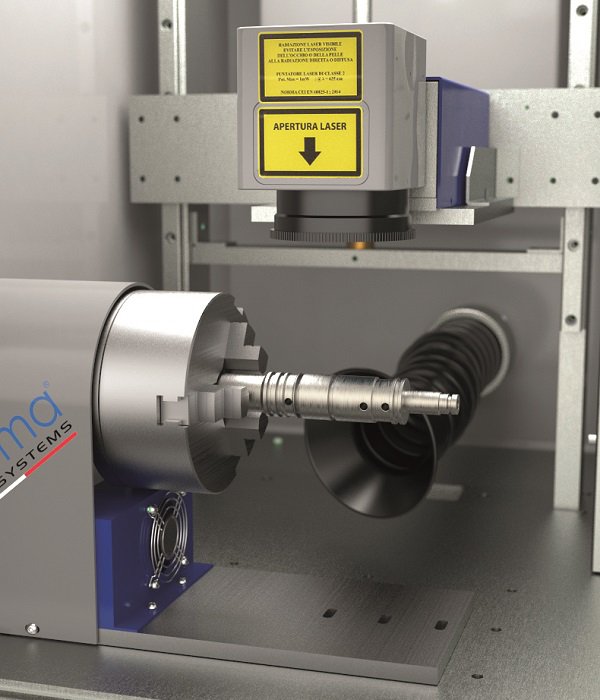

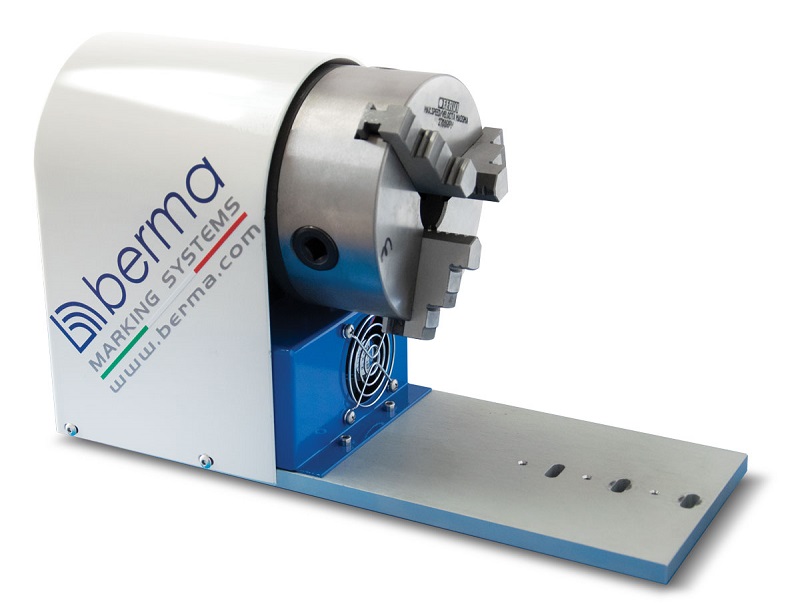

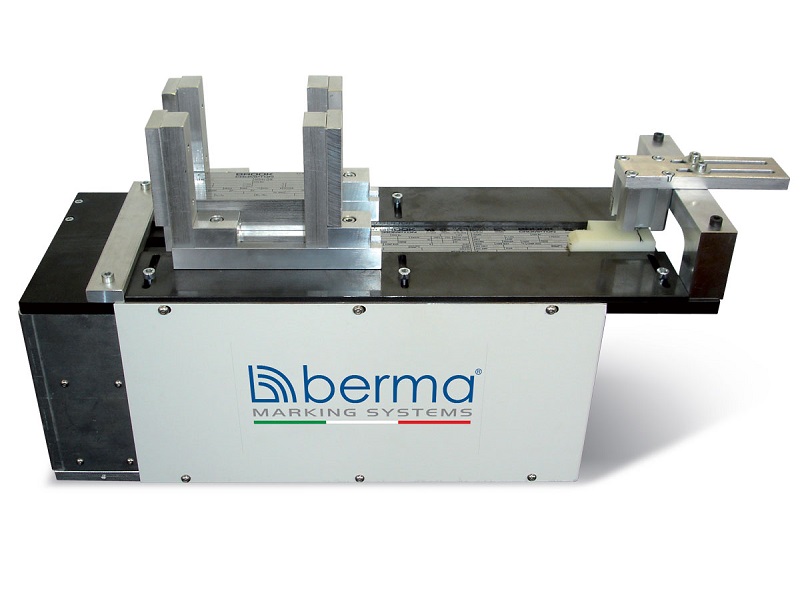

Particularly suitable for processing handy components, single or in small batches, it also allows the use of optional rotary axis devices for marking cylindrical pieces and plate loader.

It can be equipped with 20W or 30W fiber laser sources, depending on the required marking speed / depth.

The movement of the Z axis is motorized and controlled by the machine firmware in order to manage the focal distance as a parameter of the marking layout.

The internal lighting and the pointing system, combined with the ease of use of the Identify3 software supplied, allow you to quickly set up the marking layout, optimizing setup times.

There is also provision for the extraction of any fumes / dust produced in the marking process, to which it is possible to connect an evacuation system with adequate filtration.

Technology, Ergonomics, Innovation, Made in Italy:

Feature and advantage:

-

Marking Area

112 x 112 mm (F163 lens)

174 x 174 mm (F254 lens)

High-capacity and regular-shape loading compartment -

Illuminated worktop

-

Integrated red point

-

Hardware integrated inside the device

-

USB, RS-232, TCP/IP (optional) connections

-

Stand alone system

-

Possibility of remote assistance

-

Easy to use and program

-

Import of BMP, DXF, DWG, PLT, SVG files

-

Laser safety Class 1 cabin with inspection window

-

Reduced maintenance

-

Long laser lifetime

Would you like to learn more?

Contact us“BERMA’s staff help you to find the best solution, standard or customized, for your needs of identification and marking”.

Rotary axis (W)

Rotary axis (W)

Vacuum cleaner systems

Vacuum cleaner systems

Plates feeder (F)

Plates feeder (F)

netTAP 50 Profinet gateway

netTAP 50 Profinet gateway